PVCu Windows have improved substantially in recent years. Today you will find some high-quality plastic windows that are extremely energy-efficient, very secure and with fine detailing.

There are premium uPVC windows available such as authentic sash windows, timber alternative and timber replacement windows as well as flush sash windows. You will also find PVCu windows that have vastly improved their foils to make them look better than the PVCu wood grain windows of previous years.

Compare aluminium and PVCu windows side by side and decide what is better made.

Even the best upvc windows, are manufactured in a way that is completely different from aluminium windows. This will be particularly evident in the window corners and where the window mullions and transoms meet the frame. On PVCu windows that have a welded and not a mechanically joined construction like aluminium there can be inconsistencies in the way corners are manufactured and cleaned that with some PVCu windows is nowhere near the high quality of a hand assembled aluminium window.

There are of course, fantastic PVCu windows such as those from Masterframe, Residence 9, Liniar and many others that are mechanically joined to replicate traditional joinery and these windows have a far better corner construction than their welded counterparts. However, if you are very particular about the quality of your windows, it is worth looking at how these windows are finished and you will quickly see the advantages of the aluminium window construction over PVCu.

How are the corners joined on a PVCu and an aluminium window?

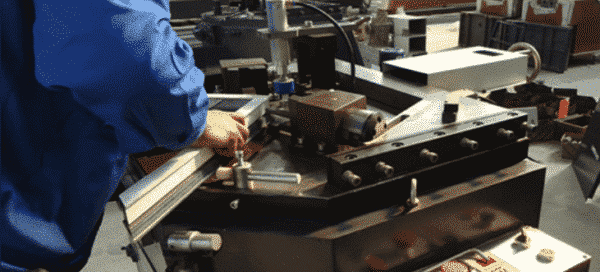

UPVC windows with welded corners are placed in a welder. They have both corners placed against a hot plate with a non stick sheet that heats and melts the plastic. Once this is done the plate moves out of the way, the heated corners are fused together and bond as the corner of the window cools.

Once the weld has cooled, there is overspill on the corner that needs to be cleaned off. This is placed in a corner cleaner which uses a sharp metal component to clean the overspill off the corner and create the finished window. Often this corner will also be hand checked to ensure it is done correctly and a manual tool may be used.

In both processes, the operator needs to stand away from the machinery.

On an aluminium window, this process is by hand. The corners have cleats and chevrons applied to the inside of the aluminium profile. Small gap sealant is applied to weather seal the corner and they are then placed in a crimper. The sides of each corner will be connected using the human eye and then the window will be crimped to mechanically bond the finished corner.

There are mechanical corner crimpers available that can automate this process, but even many of the best and largest aluminium window manufacturers prefer to use hand crimpers rather than mechanical as the finished process by hand creates the superior corner.

In this process, the operative remains close to the window to check the quality of the corner.

Comparing the welded corner against the hand assembled aluminium window.

The differences in finish on a PVCu and an aluminium window are very easy to see. When you compare the two finished windows. The corner cleaning of the PVCu window can sometimes be irregular and it’s rare to see four identical and consistent corners on plastic windows. Aluminium windows tend to have much more consistency on all four sides.

The welded corner found on a PVCu Window does have advantages.

One advantage of the welded corner used in PVCu windows is that these corners are completely sealed from any possible water ingress because they are welded together. This is different from an aluminium window that has corners mechanically joined as they cannot be welded on most standard windows. Is this an advantage?

It is fair to say that there are obvious advantages to a welded window with completely weathertight corners, but it is unlikely that driving rain or extreme weather would focus purely on the window corners rather than the overall window itself. It is also important to consider that all types of windows, irrespective of their construction have to undergo industry recognised testing for air, wind and water penetration.

Therefore, if a window has passed these tests under controlled conditions then both types of windows are considered weather resistant under the conditions set down by industry tests and standards. Both welded and mechanical corners would undergo the same weather performance testing.

In the case of aluminium windows, manufacturing must be carried out in accordance with the fabrication manuals of the systems company that designed it. These fabrication manuals will insist that small gap sealant is used before the window mitres are assembled to ensure a good seal exists where the two corners of an aluminium window meet, seal and are crimped together.

What about the window mullions and transoms?

The mullions and transoms on a upvc window are still welded together in the same way as the outer frames and vents. You will often see a V Groove on plastic window which is part of the manufacturing process, although PVCu windows can also be mechanically joined at the mullions and transoms.

Aluminium Windows all have mechanically joined mullions and transoms and typically this creates a much cleaner mullion and transom than a upvc window.

You will always find windows of different quality.

It is very important to remember that the manufacturing process of PVCu windows is just one of many reasons why they are cheaper than aluminium windows.

There are many different sorts of upvc and aluminium windows available and you will see different features in the construction of each.

However, the joining process of aluminium windows is largely the same across all products and the manufacturing process of aluminium generally produces a much cleaner, smoother and better finished window.

The welding process of plastic windows will also vary from product to product but it is important to remember that in making plastic windows, all processes are largely automated whereas aluminium windows remain hand made and assembled like traditional joinery.

So next time you are in a window showroom looking at both PVCu and aluminium windows, have a look at how the corners and window mullions are joined and made on both systems and decide what window you prefer the look of.

Contact us for further information and where to buy the current range of aluminium window for your home.