When it comes to the colouring and finishing of aluminium, polyester powder coating is the most popular method used.

For over forty years, the powder coating process has been extensively used for colouring architectural aluminium, commercial aluminium and the windows and doors used in the home.

It is very important to remember that in the majority of construction projects untreated aluminium (also known as mill finish aluminium), must be treated in order to avoid oxidisation, discolouring and damage.

One method of finishing that is not as widely used as powder coating is Anodising. Anodised aluminium has been in existence for over 70 years – far longer than the powder coating process.

What is Anodised aluminium and should you consider it for commercial and residential projects?

What is anodised aluminium?

Anodising varies quite a lot from the powder coating process. When anodising aluminium, the finishing process is such that at the end the appearance of the aluminium profile is completely different.

Anodising is generally a “metal” appearance on aluminium that when seen up close is remarkably attractive.

At the same time anodised aluminium is still expected to offer protection from the elements and of course offer resistance to colour fastness and be durable.

How is aluminium anodised?

The anodising process is quite technical. In creating an anodised finish, it is necessary to pass an electric current from cathode to anode.

It may help to explain what is a cathode and anode. The Anode and Cathode are determined by the flow of the electrical current. The cathode is the negative charged electrode and attracts the positive charge. The anode is the positive electrode.

Therefore the aluminium extrusion becomes the anode and the anodising tanks typically used are the cathodes.

This process results in oxygen and the aluminium reacting to create aluminium oxide that is the anodising film forming the coating. The longer the extrusion is left in the anodising tank under this process, the thicker the coating.

Polyester powder coating is typically 60 microns. Anodising is up to 30 microns.

How is colour applied to anodised aluminium?

Different colours require different colouring methods. A professional anodiser will use Electrocolouring for the darker anodised colours or a combination method for the more natural colours such as silver.

What is the difference between powder coating and anodising?

There are many differences between polyester powder coating and anodising. The first is how the material is pre-treated. Powder coated aluminium goes through several different cleaning and pre-treatment processes before it can be painted.

However the main difference between powder coating and anodising is that powder coated aluminium effectively has a coloured “film” or “coat” over the mill finish aluminium. By comparison, anodising blends and integrates with the aluminium extrusions. This results in a different looking colour, texture and finish.

Anodising is instantly obvious as a more transparent finish and one that gives an appearance of being as one with the aluminium rather than an external coat of paint.

Anodised aluminium, unlike powder coated appears natural, reacts differently to light conditions, sunlight and artificial light. it also has a wonderful contemporary metallic sheen.

What is better? Anodising or Powder Coating?

Anodised aluminium looks fantastic and feels completely different to powder coated aluminium. Unfortunately it is rarely seen in residential aluminium door and window installations. It was very popular in early double glazing and it is often the case you will see silver windows and doors in hardwood subframes.

Some systems companies such as Schuco still offer anodised aluminium as a stock product, however the vast majority have opted to stock powder coated aluminium instead.

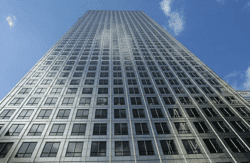

Ultimately, aesthetics play a part in what finishing process is chosen. Architect still favour anodised aluminium in modern commercial buildings.

Anodising has changed over recent years to now offer more colours, textures and shades. But if you are after a true contemporary metallic shade, it is well worth researching anodised aluminium and seeing samples.

Whilst powder coating is cheaper, long lasting, durable, comes in a huge number of colours and is the popular choice, anodising does actually offer several advantages over powder coated aluminium. These include:

- Subject to installation, anodising can come with a lifetime guarantee.

- A natural looking finish that reacts to light

- Exceptional resistance to corrosion

- Unlike powder coating there is no “adhesion failure”.

- Will not fade. Powder coating will lose colour over time.

- Anodising cannot peel off over time.

- It is harder and more durable than a powder coated finish.

The above advantages do not mean that powder coating is substandard. It is very important to know that powder coating when carried out correctly and by a qualified applicator such as those approved by Qualicoat, will provide a long lasting and durable finish. However the nature of anodising does provide benefits in construction that powder coating can’t and can ultimately create an exterior finish that will last a lifetime.